|

Biogas technology uses a biological process to produce a combustible gas from the decomposition of organic waste in an anaerobic setting. The gas, known as biogas, contains roughly 60% methane and 40% carbon dioxide and can be converted to provide usable energy: gas, electricity and heat. Other valuable by-products include pathogen-free organic fertilizer and animal bedding.

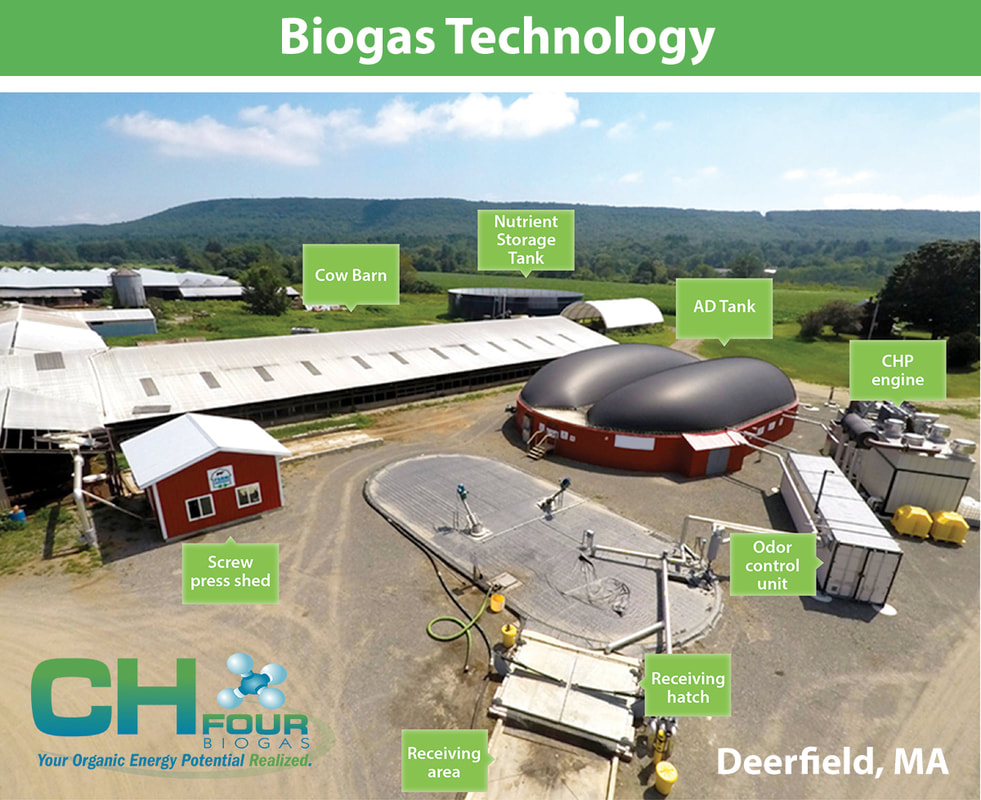

CH Four Biogas offers complete-mix anaerobic digester systems in sizes to suit our customers' needs in the agricultural, municipal and industrial arenas. Our systems are designed to accept a wide range of carbon-based feedstocks, including livestock manure, digestible manufacturing waste, pre- and post-consumer food wastes, and more. While our digesters operate in the mesophilic temperature range (around 104º), it is the complexity of the feedstocks that determine the additional need for various pre-processing facilities and digestion stages. Our systems are designed to maximize overall system performance in terms of gas quality and quantity and long-term reliability. There are no unusable waste products associated with a biogas system. The biogas produced can be scrubbed and used as fuel in specially designed motors. Often it is used in CHP (combined heat and power) units where it is turned into electricity and heat. It could also be upgraded to biomethane. The produced heat is recycled to the system and can also be used in another process or the surrounding facilities. After the digestion process, the slurry - or digestate - itself is an organic fertilizer that can be land-applied as is. It has shown to improve soil fertility and crop yield over time. Additionally, the solids from the slurry can be separated out and used as animal bedding or part of compost. Most noteworthy is that the digestate presents with minimal odor - a reduction of up to 97% - in comparison with conventional manure. |

Call today for your FREE estimate!

|

Cesar Rios

Organics Diversion Specialist TF: 1-800-418-7304 C: 951-377-4888 Cesar@Riosorganics.com 1588 Batavia St., Suite 1 D Orange, Ca 92867 |